| C3224 | 2000 kN Automatic Four Column Compression Testing Machine EN, 220-240 V 50-60 Hz |

| C5224 | 2000 kN Automatic Four Column Compression Testing Machine ASTM, 220-240 V 50-60 Hz |

| C5224/110 | 2000 kN Automatic Four Column Compression Testing Machine ASTM, 110 V 60 Hz |

| C3228 | 3000 kN Automatic Four Column Compression Testing Machine EN, 220-240 V 50-60 Hz |

| C5228 | 3000 kN Automatic Four Column Compression Testing Machine ASTM, 220-240 V 50-60 Hz |

| C5228/110 | 3000 kN Automatic Four Column Compression Testing Machine ASTM, 110 V 60 Hz |

| C3224 | 2000 kN Automatic Four Column Compression Testing Machine EN, 220-240 V 50-60 Hz |

| C5224 | 2000 kN Automatic Four Column Compression Testing Machine ASTM, 220-240 V 50-60 Hz |

| C5224/110 | 2000 kN Automatic Four Column Compression Testing Machine ASTM, 110 V 60 Hz |

| C3228 | 3000 kN Automatic Four Column Compression Testing Machine EN, 220-240 V 50-60 Hz |

| C5228 | 3000 kN Automatic Four Column Compression Testing Machine ASTM, 220-240 V 50-60 Hz |

| C5228/110 | 3000 kN Automatic Four Column Compression Testing Machine ASTM, 110 V 60 Hz |

Testmak series HS Four Column Automatic Concrete Compression Testing Machines are designed for reliable and consistent to do the of compressive strength tests of different sizes concrete cylinder and cube moulds of samples.

Compressive strength test machines are manufactured in accordance with international TS EN 12390-3, 12390-4 ASTM C39, AASHTO T22 and TS EN ISO 7500 standards. It also meets the requirements of all CE norms related to operator health and safety.

Concrete compression test machines are produced in Class 1 starting from 50 kN. The upper platen adjusts itself to apply homogeneous loading on the sample. Upper and lower platens are in accordance with international specifications. Surface hardness is 55HRC, flatness tolerance 0.02 mm. Traceable certificate of surface hardness is shipped with the device on request.

Experiments can be performed than on automatic control and data acquisition unit or with the free TCM200 computer software. Tablet and smartphone applications are also available optional. Can do test by connecting with smartphone ot tablet the machines via wireless internet (Wifi ) and can perform print test report, from the thermal printer or via computer software with desctop printer. (reporting, graphic output, etc.)

Thanks to its easy use, it allows operators with little experience to do the tests without any trouble.

• The concrete samples is centered on the compression machine`s lower loading plate.

• Choosing the sample to be tested.

Advantages of TCM200 touch screen control and data acquisition unit

1-) Values of 100, 150, 200 mm concrete cube samples such as dimensions, test speed and fracture sensitivity rate are automatically predefined in the device.

2-) Values of 100*100, 150*300, 160*320 mm concrete cylinder samples such as dimensions, test speed and fracture sensitivity rate are automatically predefined in the device.

3-) If you want to enter special values, you can easily change or add them on the touch screen.

• Pressing the "Start" button on the control unit.

• The machine starts loading at the set test speed. When the sample is broken, it automatically stops and returns to its initial state.

• Experiment result and test parameters are automatically saved.

Safety Features

Maximum pressure valves to avoid machine overloading

Limit switch (for piston stroke)

Emergency stop button

Removable transparent front and rear safety doors

Software controlled maximum load value

Security Switch for to stop the machine if the door is opened during a test.

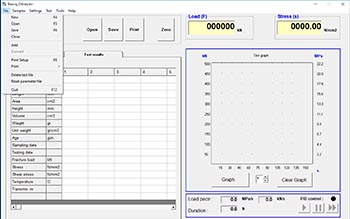

TCM200 Touch Control Unit

TCM200 Touch Control Unit is designed to perform automatically compression, flexure and splitting tensile strength tests of construction materials such as concrete, cement mortar, masonary units/blocks by controlling the Testmak automatic compression / flexure testing machines.

All the operations of TCM200 Touch are controlled from the front panel touch screen display.

TCM200 Touch Control Unit has easy to use menu options. It displays all menu option listings simultaneously, allowing the operator to access the required option in a seemless manner to activate the option or enter a numeric value to set the test parameters. Digital graphic display is able to draw real-time "Load vs. Time", or "Stress vs. Time" graphics. Can do calibration easily from 10 points. Manual Control is available.

Technicial Features for TCM200 Touch Screen

• Color TFT touch display supports 16M colors and supports 800x480 pixel screen resolution

• 3 pcs universal analog input sockets (ADC)

• Each analog input with 18 bit precision (1/256000)

• 1 replacement analog input

• Total of 4 analog high-precision measuring capacities

• 2 analog output sockets (DAC)

• PULSE / DIR outputs (PULSE / DIR / ENA) to control the servo and stepper motor drives.

• Digital outputs for general purpose (can pull relays and control different electrical units)

• Digital inputs for general purpose (receives and evaluates input signals like limit contacts from the environment)

• Potentiometer input (reference signal input for calibration and remote control)

• USB communication signal output (communicates with computers)

• Connects to local networks and the Internet with Ethernet 10/100 network connection output (optional)

• Connects to portable devices via Bluetooth wireless connection (optional)

• 500 test results can be stored in internal memory

• Due to the SD (memory) card connection, a large number of test results can be stored in the device memory (40,000 test results).

• In addition, the results can be taken from the device memory and transferred to the computer as an Excel table. (Optional)

• Resistive touch screen allows easy operation of device functions by touching the screen

• Sensor modules are compatible with loadcell (load cell), pressure sensor (4-20 / 0-20 mA), potentiometric distance sensors, strain washers, thermocouples and all kinds of mV output sensors.

• Provides precise calibration with multi-point calibration (up to 10 points)

• Setting and calibration menus are password protected and prevent unauthorized use

• Allows testing with a computer, tablet, smartphone or on the touch screen panel.

• There are many test sample information screens and test methods in the device memory and tests can be performed easily

• Different menu languages can be selected via the device via language support (Turkish, English, French, Spanish and Russian)

• Speed control algorithm is closed loop PID control and all parameters can be adjusted on user side.

• The device can switch between one-touch load and deformation control modesCihaz farklı makinelere kolayca adapte edilebilir ve en uygun kontrol sağlanır

• The graphical field that visualizes the test results on the screen has the ability to change the scale automatically and automatically adjusts the optimal scale as the values change

• Firmware updates can be made via USB input. In addition, via the computer allows remote or internet update.

TCM200 Touch Software for Automatic Compression / Flexure Testing Machines

TCM200 Touch software provides to perform automatically compression, flexure and splitting tensile strength tests of construction materials such as concrete, cement mortar, masonary units/blocks by controlling the Testmak automatic compression / flexure testing machines.

HS Four Column Automatic Compression Testing Machines send complete with following accessories;

1- Spacer Discs;

For ASTM Standards;

• Diameter 165 mm x Height 90 mm spacer disc 1 piece

• Diameter 165 mm x Height 50 mm spacer disc 1 piece

• Diameter 165 mm x Height 30 mm spacer disc 2 piece

For EN Standards;

• Diameter 205 mm x Height 90 mm spacer disc 1 piece

• Diameter 205 mm x Height 50 mm spacer disc 1 piece

• Diameter 205 mm x Height 30 mm spacer disc 1 piece

2- Upper Platen;

• Upper Platen Diameter 165 mm (with ball seating assembly) (For ASTM Standards)

• Upper Platen Diameter 300 mm (with ball seating assembly) (For EN Standards)

3- Lower Platen;

• Lower Platen Diameter 165 mm (For ASTM Standards)

• Lower Platen Diameter 300 mm (For EN Standards)

4- Piston;

• Piston Diameter 250 mm (For 2000 kN Capacity Models)

• Piston Diameter 300 mm (For 3000 kN Capacity Models)

5- Automatic Hydraulic Power Pack ;

• Automatic Hydraulic Power Pack, 410 bar (For All Models)

P.CODE |

C3224 |

C3228 |

C5224 |

C5228 |

|---|---|---|---|---|

Capacity |

2000 kN |

3000 kN |

2000 kN |

3000 kN |

Standard |

EN |

EN |

ASTM |

ASTM |

Lower Platens Dim. |

Ø300 mm |

Ø300 mm |

Ø165 mm |

Ø165 mm |

Upper Platens Dim. |

Ø300 mm |

Ø300 mm |

Ø165 mm |

Ø165 mm |

Vertical Clearance |

340 mm |

340 mm |

370 mm |

370 mm |

Horizontal Clearance |

360 mm |

425 mm |

360 mm |

425 mm |

Piston Diameter |

250 mm |

300 mm |

250 mm |

300 mm |

Max. Piston Movement |

50 mm |

50 mm |

50 mm |

50 mm |

Max. Working Pressure |

410 Bar |

410 Bar |

410 Bar |

410 Bar |

Oil Capacity |

18 L |

18 L |

18 L |

18 L |

Power |

1100 W |

1100 W |

1100 W |

1100 W |

Dimensions (wxlxh) |

850x550x1400 mm |

980x680x1500 mm |

850x550x1400 mm |

980x680x1500 mm |

Weight |

870 kg |

1100 kg |

850 kg |

1050 kg |