Universal Hydraulic Tensile Test Machine is produced to test the ferrous materials for structural values such as yield strength and tensile strength.

Universal Hydraulic Tensile Test Machines can also be used for compression tests up to the capacity of the machine. Maximum capacity is 400 to 1000 kN. Can be test flat and round samples. 0-40 mm flat and 8-32 mm round samples can be tested with a hydraulic jaws that comply with standards.

Load cell is used for load measurements. Strain measurement is done by the electronic displacement transducer built in the machine if required external extensometer fitted to the specimen also can be used for strain measurement. Strain measurements can be done directly from the extensometer fitted to the specimen.

Tests can be done automatic by digital control unit or computer. Machine complete the test with the set pace rate and turns to start position automatically.

Hydraulic Universal Testing Machine, features two test spaces for tension tests and compression tests.

The distance between the grips can be set by motor driven hand set system. With open front hydraulic wedge grips user can load specimen easily.

LOADING CYLINDER ASSEMBLY

700 bar hydraulic cylinders are ideal for many applications. Hydraulic cylinders, which are preferred especially in applications with a long lifting distance, offer solutions with both lifting capacity and stroke length of 100 mm.

FEATURES

• 700 bar hydraulic cylinders with 10-550 tons options

• Stroke option between 50-320 mm

• 2 types as single and double acting model. Double acting models, with hydraulic oil return system.

• Made of high quality crack-controlled 4140 steel.

• Horizontal or upside down, suitable for working in any direction

• Safe working opportunity with the safety valve included in the system

• Piston system is chrome plated against corrosion

COMPRESSION PLATENS

Compression platens are used to perform compression tests on a wide range of materials and components. When installed in a Universal Testing Machine they allow a variety of tests to be performed to determine compression modulus, compression strength, and compression yield strength. Diameter: 150xh50mm

EXTENSOMETER

Different types of extensometers with accuracy of ±0.1% of indicated value are available depending on requirements. Extensometer can directly measure deformation of specimens.

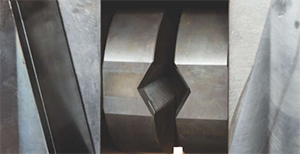

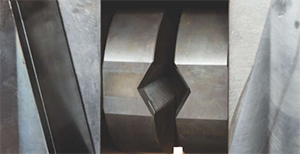

HYDRAULIC GRIPS

Hydraulic grips are very safe. Hydraulic grips come with grip sets for pulling 8 – 32 mm diameter cylinder samples. The hydraulic grips has an independent hydraulic power unit with a working pressure of 400 bars. Jaw faces for flat samples should be ordered separately.

LOAD CELL

It is a high precision load cell operating in compression and tension directions, produced in various capacities from 20 Tons to 100 Tons.

With its nickel-plated alloy body and hermetic sealing, It provides reliable precision in demanding industrial applications.

Applications

• Force testing machines

• Tensile tear test machines

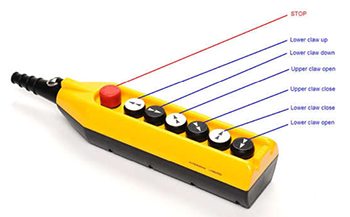

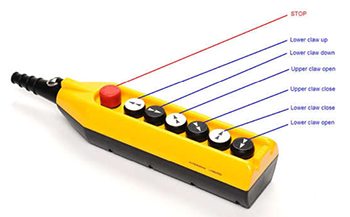

HAND CONTROL

This hand-held unit is used for positioning the upper cross-head, to suite the sample height, and to tighten the grippers on the sample before testing.

DATA ACQUISITION & PC SOFTWARE

The Universal Testing machine can be controlled (Start, Stop commands) by a computer with the software (given free of charge by TESTMAK). This software provides data acquisition and management for compression, tensile and splitting tensile test throughout the test execution. The advanced functions for data base management provide an easy navigation of all saved data. The test results certifi cate includes all descriptive information. Therefore, test parameters can be set and details about the test carried out such as client details, test type, specimen type, user info and other information required can be entered and printed out as well as test report and graph.

TCM304 Software is developed for testing tensile strength of Reinforcing Rubbed Steel Bars and Welded fabric for the Reinforcement and Prestressing of Concrete. The software includes control of machine, data acquisition, saving them and preparing reports. The user can prepare his own report and also can send the results to Microsoft Excel environment. The software accepts sample’s weigth, length, diameter and gauge length as input, and then the user can give start test command to the machine. The samples calculated diameter gives user a perspective about the density of rebar prior to the test.

The software continously updates load,stress and elongation percentage till the break point. When the test is completed the yield point is calculated and indicated on the graph. Each report is a group of 42 samples where 14 different diameters had been entered. The software is prepared as making at least 3 samples for each diameter. This gives user a total report about all the batch.The report includes all standart limits and one can easily check whether the sample can be acceptable. These limits are minimum yield, minimum tensile, minimum break elongation value,Tensile per yield ratio etc. The user can zoom on the graph for further inspection Break elongation value can be syncronized with the manual measurement after the test has been completed for the users that do not use extensometer.

• Foreign Language Support and Customizable User Interface

All contents of experimental data and additional information can be organized by user. Software can be performed in x different languages.

• Capability to Save 24 test results of different specimens in one test folder

Test results, graphics and properties of 24 different specimens can be saved in one folder. Old test folders can be reviewed and be edited easily. Advanced

Graphic User Interface Software

• Graphical data on the screen is refreshed simultaneously during test procedure

Load values can be monitored in high resolution graphics at every 100 milliseconds. User can highlight all 24 different specimen curves or preferred ones in different colors on the graphics. Zooming in–out and dragging can be done easily by mouse. Peak values of curves can be marked on the graphics and user can get load value of any point on the graph via high resolution.

• Able to save frequently used texts in memory and recall them when necessary

Frequently used information like name and location of the laboratory, type and dimensions of mostly used specimens are held in memory and can be written automatically by right clicking on information boxes and selecting frequently used text in menu.

• Capable to Access and use previously done test data

User can access any data of previously completed tests and use in his/ her new report since most of the tests have same structure and properties.

• Able to edit test parameters of the testing equipment through Software

All test parameters supported by testing equipment can be changed remotely via software. All test parameters specified by user are downloaded to the device before initialing the test procedure. By this way predefi ned device parameters will not cause errors in test results

• Graphical outputs and reports can be saved as a MS Excel worksheet

Test result parameters and graphics are transferred to MS Excel worksheet properly to give user a chance to edit any

data and graph easily.

• Maximum Flexibility to edit report and graph templates

User can design his/her custom report template and graphic scheme in MS Excel. In software part, user will defi ne which data will be screened in which cell on the worksheet. Therefore , he/she will be able to monitor test results in his/her specific design.

![]()